This is the first part of a three part story of a business that continues today, first as the "Ballarat Pottery Works Pty Ltd" run by George Marks. The second was Martins Stoneware Pipes, and finally, the third incarnation, Vitclay.

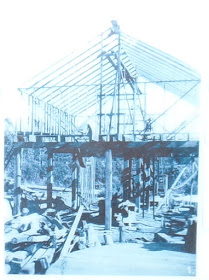

This photograph of the Ballarat Pottery Works was taken shortly after Martin's takeover in 1921. The buildings in the picture were destroyed by fire in 1922. You can just make out Martins sign to the left of the door.

George

Marks was one of the early potters in Ballarat. Unlike so many others, he had

not made his way to the goldfields in search of

riches. He arrived in Victoria aboard the SS Norfolk in 1858 from London. Like so many others, fortune did not happen, although he did become a

shareholder in the Windsor Gold Mining Company in August 1864 and the

Nairnshire Gold Mining Company in 1871.

He had accepted an offer to work at a works in Brunswick,

Victoria as a potter. Although a Londoner, George had trained at the Doulton and Sons

pottery in Staffordshire.

In 1861, George Marks established

his first Ballarat Pottery Works on Creswick Road in Ballarat, near the Old

Cemetery. There with the help of four boys he produced salt-glazed drain pipes,

chimney pots and tiles for Ballarat builders as well as a quantity of

wheel-thrown jars, flower pots and saucers, water monkeys, bread pans, butter

pots, ginger beer bottles, etc. The business flourished and the building of the

railway through his property gave him the opportunity to relocate closer to

town at 306 Creswick Road.

Principally, the reason was that he could not obtain title to the land

near the cemetery. Clay was obtained

from a number of sites around Ballarat.

The first building on the new

site was a two-storey timber framed construction of 47 feet by 90 feet. The triple fronted timber building with the

square chimney was later built. (Square

chimneys are usually of Welsh manufacture whereas circular chimneys are usually

Cornish.) Another chimney was built on

top of a circular two-storey kiln containing three furnaces. This wood and

coal kiln was used to fire flower pots and chimney ornaments. A second coal only fired kiln nearby was

lined with firebricks made by Taylors Brickworks at Black Hill.

A

ten horsepower horizontal steam engine was also installed to operate the

machinery at the plant. The initial

processing of the clay was carried out at the rear of the property by a horse

drawn pug mill. Different products

required different grades of clay. The pug mill worked the clay to a

proper consistency that was then moved in large lumps into sheds ready to be

converted into various articles. The

clay that is now pretty solid and “stiff” is then placed in a small press with

a perforated bottom. The press was

worked by hand, and after the clay had passed through the perforated bottom it

was almost free from stones and fit to be made into the rougher articles, such

as flower-pots and tiles. The clay from

which ginger-beer bottles, water monkeys, preserve pots etcetera, were made was

all carefully washed in tubs and worked up by hand before it was put upon the

potter’s lathe.

The following comes from a newspaper article

from “The Star”. “but by far the most

interesting of the work is that done by Mr Marks on the potters lathe or

wheel. The potter’s wheel is a small

iron table made to revolve by means of cog-wheels upon a handle like that of a

windlass being turned. Upon this wheel,

or revolving table, the potter makes flower pots and saucers, water monkeys,

bread pans, butter pots, ginger beer bottles, and various other things. The potter from practice knows the size of

the piece of clay he will require for any particular article. He takes this lump of clay, puts it on the

wheel, dips his hands in water, and the boy in attendance sets the table

revolving rapidly. In a few seconds the

operator, using only his hands and a small piece of tin for a scraper will turn

out such small articles such as ginger-beer bottles, blacking pots, and small

jars of all shapes and so quickly does he do it that the operation appears like

a sort of magic to one who knows nothing of the work.

The

larger articles, such as 6 and 7 gallon butter jars, or large bread pans

capable of holding five or six loaves, are more difficult and take longer to

make, but Mr Marks turns out any of these out, perfectly formed, in less than

five minutes. The trueness of curve and

shape generally in all these things seems wonderful, for the potter does his

work with great speed and has only his hands and eyes to guide him. Chimney pots of all sizes and shapes are

made by Mr Marks. The plain round ones

are made with the press in the same manner as the pipes, but the octagonal

pots, moulded in the ordinary way with wooded moulds, and the sectional pieces

are afterwards joined together. Some of

the designs here for chimney pots are very pretty, and there were all kinds of

wonderful inventions for doing away with the smoky chimneys. Some of the Ballarat builders deal largely

with Mr Marks for chimney pots, and he turns out a large number weekly.

The clay for the manufacture of the rougher

kinds of wares, such as pipes and chimney pots does not need to be very fine,

and after a very slight preparation it is ready for use. Great care, however, has to be taken in the preparation

of the clay for the manufacture of such things as preserve jars, water monkeys

&c. The clay for these things is

put through the pug-mill, then puddled in a tub, and when it is of proper

consistency it is placed on a wooded table and worked up like dough only much

more carefully. Every little stone is

picked out and the clay is worked for hours before it is fit for the potter’s

wheel. After all the smaller articles

are made on the wheel they can be removed by hand, but the larger vessels being

soft cannot be handles. Before they are

made, therefore a piece of wood is fixed in the wheel and the vessel after it

is made, are removed together.

The next process is the drying. Drainpipes, tiles, bottles and jars, are all

stacked, and allowed to dry for a certain time until they are ready for baking

in the kiln. The drain pipes and

chimney pots are burned in a kiln by themselves. This kiln holds about 8000 drain pipes, and a large number of

chimney pots, and if the pottery was in

full work two kilns per week of these articles could be baked. This kiln has six fire holes, and costs £8 per week for fuel, both coal and

wood. A glaze is put on the pots and

pipes by a large quantity of common salt being thrown in the kiln at the

top. The flower pots and other small

articles are baked in a separate kiln, as they are of a frail and delicate

nature, and will not stand rough handling.

The kiln set apart for them is a small one, and is divided into small

compartments, made with large, flat, clay tiles. The flower pots are not glazed, but the jam jars and ginger-beer

bottles are glazed in the same manner as the drain pipes.

The small sized drain pipes are sold in large

quantities to farmers and others in the district, and there is a good demand

for flower pots among the gardeners and nurserymen. Mr Marks says he can manufacture drain pipes, flower pots, plain

and ornamental chimney pots, and jars of all kinds at a much lower rate than

these articles can be imported for. The

Lextonshire and Avica shire councils purchase large numbers of the 26-inch

drain pipes for culverts. Mr Marks’

chief difficulty is the want of good clay for the making of the finer sorts of

pottery ware, and he is at present experimenting with various kinds of clay

obtained from different parts of the district.

Most of the finer articles he has made up to the present time have been

made more by way of experiment than with the hope of immediate profit, although

Mr Marks is confident that the proper material he can turn out wares that will

be cheaper and of as good quality as imported wares.”

He

was also making pipes too. From small

“aggie” pipes, 2” in diameter to water pipes up to 18” diameter. Output of pipes was restricted by the space

available to dry them, leading to delay in filling orders. As the town expanded, sewage pipes were also

made in increasing numbers.

When these were made, the clay was put in the

press, but the perforated bottom is

removed, and in its place a mould was fixed, according to the size of the pipes

to be made. The press was raised from the

ground about three feet, and after the clay had been put in, a wooden table,

running with weighted cords placed over pulleys in the roof of the shed, was

allowed to run up close to the bottom of the press. Then the operator set the press in motion and as the pipe was

forced through the mould, its weight forced the table down. When the pipe was long enough it was cut off

with a piece of string and removed, and the weights caused the table to rise up

ready to receive another pipe. This was

carried on until all the clay in the press was exhausted; and the press having

been refilled with clay the operation was repeated, the moulds being altered as

pipes of different sizes were required.

The making of these pipes was the chief business carried on at the pottery,

In

1869, George won a prize of 2 for his display of “Colonial made pottery

(adapted to domestic purposes and ornament)” at the ninth Annual Spring Show of

the Smeaton, Spring Hill and Bullarook Agricultural Society.

In 1878, George left to work at the Adelaide Pottery and

Drainpipe Works, at Brompton and Caversham, leaving the running of the Ballarat

Pottery mostly to his new partner Samuel Coyte. The owner of this company was William Martin who would later buy

out the Ballarat Pottery Company in 1921.

There had been a huge expansion of the sewage system in Adelaide and

George was in the position to satisfy this demand. Martins were a well known family in Adelaide, as James Martin had

been a major manufacturer of farm machinery.

George died in Hindmarsh, Adelaide in 1918 at the ripe old age of 79

Within a few years the Ballarat

Pottery had ceased to produce domestic wares although it continued making pipes

and fittings until 1921, when it was taken over by William Martin and became

Martin Stoneware Pipe Pty Ltd. It is

impossible to accurately identify the pottery output of this pottery because so

few pieces were ever marked. This

appears to be a common element amongst the makers in and around Ballarat.